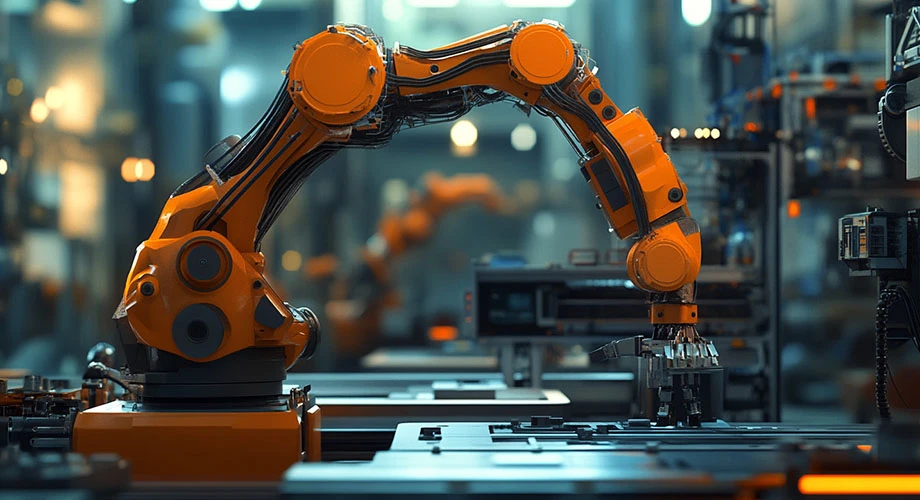

The application of industrial robot are widely used in nowadays. Carry, assemble, stacking, grinding and polishing etc. It bring along the traditional industry transformation and upgrading, increasing the new entelechy and vitality.

Contact Us

The application of industrial robot are widely used in nowadays. Carry, assemble, stacking, grinding and polishing etc. It bring along the traditional industry transformation and upgrading, increasing the new entelechy and vitality.

LYNBC could supply all kinds of precision cross roller bearing with different structure, it may with mounting hole, cage, spacer, full complement, double seals etc. the precision could reach to P5.

1. Crossed Roller Bearings

Compact design with high rigidity and load-carrying capacity

Capable of handling radial, axial, and moment loads simultaneously

Used in robotic joints, rotary tables, and precision positioning systems

2. Thin-Section Bearings

Lightweight design with minimal space requirements

Provide smooth and precise rotation with low friction

Commonly found in robotic arms and medical robots

3. Angular Contact Ball Bearings

Designed to handle both radial and axial loads efficiently

High-speed capability and excellent precision

Used in robotic gearboxes, servo motors, and spindle applications

4. Cylindrical Roller Bearings

Support high radial loads and moderate axial loads

Suitable for high-speed and high-load applications

Found in robotic transmission systems and industrial automation machinery

5. Spherical Roller Bearings

Self-aligning capability compensates for misalignment

Designed for heavy-load applications in robotic systems

Used in robotic welding arms and heavy-duty automation equipment

6. Harmonic Drive Bearings

Integral part of harmonic drive systems, which provide high torque and precision

Enable smooth and accurate movements in compact spaces

Essential for robotic joints and actuators requiring high positioning accuracy

As an experienced special bearing manufacturer and supplier in China, we can produce various bearings, including thrust bearings, roller bearings, roller thrust bearings, slewing bearings, precision crossed roller bearings,cylindrical roller bearings, taper roller bearings, thin section bearings,spherical plain bearings and other specialized bearings.

These bearings have the characteristics of stylish design, compact structure, reliable performance, low vibrating noise, and long service life. They are applicable to mining equipment, metallurgical equipment, medical apparatuses, rolling mills, generating equipment, as well as the machine building industry, paper making industry, civil aviation industry, and so on.

Precision and Accuracy: Bearings must offer minimal backlash and high rotational precision to maintain robotic performance.

Load Handling: Bearings should be able to support axial, radial, and moment loads, especially in robotic joints.

Durability and Reliability: Industrial robots operate continuously, requiring bearings with long service life and wear resistance.

Compact Design: Space constraints in robotic systems necessitate small, lightweight bearings without compromising performance.

Friction and Efficiency: Low-friction bearings help minimize energy consumption and improve movement efficiency.

Contamination Resistance: Bearings in industrial robots must be resistant to dust, debris, and harsh operating environments.

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.