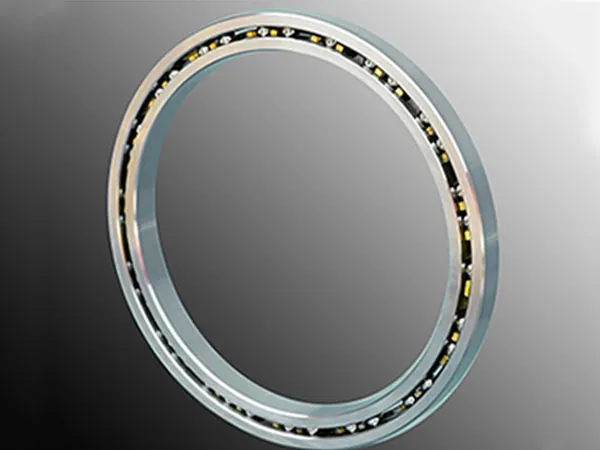

Open Angular Contact-Type A

Open Type-A angular contact bearings are a specific type of rolling element bearings designed to support both radial and axial loads simultaneously. These bearings are characterized by their angular contact, where the inner and outer rings are offset, creating an angle that allows them to handle high axial loads in one direction. The "C-type" refers to a specific design feature where the bearing has a larger contact angle compared to other types, optimizing performance under heavy loads and high speeds.

Open Radial Contact-Type C

Open C-type radial contact bearings are a type of mechanical bearing designed to support radial loads while providing low friction and high efficiency. The "C-type" designation refers to the open design, where the bearing has no seals or shields, making it suitable for applications where contaminants are not a concern or where regular maintenance can be performed. These bearings consist of an inner ring, outer ring, and rolling elements (typically balls or rollers) arranged in a way that ensures smooth rotation and minimal wear.

Open 4-Point Contact-Tppe X

OPEN 4-point contact-tppe X bearings are a specialized bearing type optimized for handling high axial loads in both directions, offering a compact and efficient solution in many applications. Understanding their strengths and limitations is crucial for proper application and performance. Always consult with a bearing manufacturer or engineer for specific application requirements.

Structures

Thin section bearings involved in radial ball bearings are a family of bearings designed from a single cross section which remains constant as the bore diameter is increased. The thin section bearing family consists of 9 primary cross section sets ranging from 0.1875×0.1875 inch to 1×1 inch and with bore diameter ranging from 1 inch to over 40 inch. The combination of a large bore diameter in proportion to the small cross section makes these parts appear “thin” in contrast to standard ball bearings.

Configure

Thin section bearings are made from 52100 chrome steel and 440C stainless steel. They can also be coated with chromium plating.

Some sizes can be configured with seals or shields(specification Nitrile Rubber). Within these families, you can generally choose between open bearings for applications where bearings will not be exposed to damaging particulates and sealed bearings for applications where bearings need to be kept clean and well-lubricated.

Type

To support various load conditions, thin section bearings are available in three basic types: angular contact (Type A),radial contact (Type C), and four-point contact (Type X), and in a variety of sizes, or series(e.g.,NBKA,NBKB,NBKC,etc.) and interchange with Kaydon KA,Kaydon KB,Kaydon KC,etc.

Cage

Thin section bearings are available with various retainer options to space the rolling elements uniformly and prevent contact between them. Retainer types available contain: continuous ring”snap-over pocket”, continuous ring circular pocket, formed wire, PTFE spacers, and spacer ball separators. Different material of separators are available for unusual operating conditions including stainless steel, brass ,aluminum and non-metallics composite such as phenolic laminate, PTFE,PEEK and reinforced nylon.

Features

Thin section bearings featured as saving weight, creating space, reducing friction, increasing design flexibility and providing excellent running accuracy which that is applied for special operation conditions. Especially in the case of medical equipment, airborne optical and robotics, the space and weight requirements of a system are major factors in overall design and manufacturing cost.

Technical Support

The design’s of all these precision thin section bearings are based on standard structures; LYNBC can design and manufacture many other similar structures in accordance to the special and particular requirements of their customers’. If our customer’s have specific requests then the customer should identify the structure, and mounting dimensions that are required. Please contact the LYNBC Technical Center if you need any assistance in this area.

Type of Lubricant: Use the recommended grease or oil, considering the operating conditions (e.g., temperature, load, and speed).

Application: Apply lubrication in small amounts to avoid over-lubrication, which can cause overheating.

Re-lubrication Schedule: Follow manufacturer recommendations based on usage and environment.

Contamination Control: Keep the area free from dust, dirt, and moisture to prevent premature wear.

Sealed Bearings: If applicable, ensure seals are intact to prevent contaminants from entering.

Visual Checks: Look for signs of wear, pitting, or corrosion.

Noise & Vibration Monitoring: Unusual sounds or vibrations may indicate misalignment, contamination, or lubrication issues.

Torque Testing: If resistance increases, it could be a sign of lubrication failure or contamination.

Storage Conditions: Keep bearings in a dry, temperature-controlled environment, ideally in their original packaging.

Handling Precautions: Avoid dropping or impacting the bearing, as thin-section bearings are more susceptible to deformation.

Correct Fit: Avoid excessive force during installation to prevent raceway deformation.

Alignment Check: Ensure proper alignment to prevent uneven load distribution, which can cause premature failure.

Preload & Clearance: Follow manufacturer specifications to ensure the right preload or clearance is maintained.

Timely Replacement: If a bearing shows excessive wear or damage, replace it to avoid failures in critical applications.

Track Maintenance Records: Keep a log of maintenance activities to track wear patterns and optimize replacement schedules.

If you are interested in our products and services,

please feel free to contact us!

Get in tuch

+86-379-60689957

Lianmeng Road, Jianxi district, Luoyang City,Henan province.